Define the term “bleed area” in print design and its significance in apparel printing.

INTRODUCTION

In the realm of print design, precision is everything. One of the key technical concepts that ensures a flawless, edge-to-edge finish is the “bleed area.” Often misunderstood or overlooked by beginners, the bleed area plays a crucial role in avoiding white edges, misalignments, or design inconsistencies during the printing and cutting process. This concept is especially important in apparel printing, where designs often span the entire garment or need to align seamlessly with the fabric’s edges. Below is a clear definition of the term and an explanation of its importance.

DEFINITION OF BLEED AREA

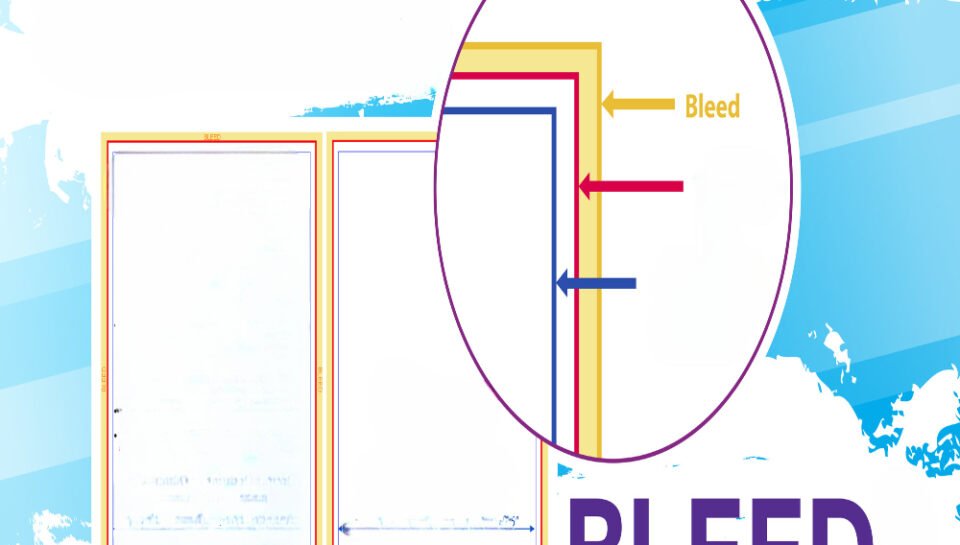

The “bleed area” refers to the portion of a design that extends beyond the actual trim or cut line of the final printed product. Typically, this extra margin is 1/8 inch (3mm) or more, depending on the printer’s specifications. The purpose of this area is to ensure that the printed image covers the entire surface up to the edge, even if there is slight movement or shifting during cutting or printing.

SIGNIFICANCE IN APPAREL PRINTING

1. PREVENTS UNWANTED WHITE EDGES

In apparel printing, particularly in sublimation and all-over printing, any design that doesn’t extend into the bleed area risks leaving unprinted fabric along the seams or edges. This can ruin the final appearance and reduce product quality.

2. ALLOWS FOR PRECISION AND ALIGNMENT

Fabric can stretch or shift slightly during production. The bleed area acts as a safety buffer, allowing for slight variations without compromising the visual integrity of the design.

3. SUPPORTS FULL-PANEL AND EDGE-TO-EDGE DESIGNS

For designs that cover the entire front, back, or sleeves of a garment, the bleed ensures that the image flows off the edges, giving a seamless and professional finish.

4. CRUCIAL FOR TEMPLATE-BASED LAYOUTS

Most apparel printing platforms (like Printful or Teespring) provide design templates with marked bleed zones. Following these ensures the uploaded artwork is compatible with automated print systems and yields consistent, high-quality results.

5. AFFECTS PRINTING ACCURACY IN MASS PRODUCTION

In high-volume runs, small alignment issues can scale into major quality control problems. A well-planned bleed area minimizes printing errors and supports smoother production workflows.

CONCLUSION

The bleed area is a small but essential aspect of print design that guarantees edge-to-edge coverage and a clean, professional look—especially in apparel printing. By extending your artwork into the bleed zone, you safeguard against production mishaps, preserve design intent, and enhance the final product’s visual impact.

HASHTAGS

#BleedArea #ApparelPrinting #PrintDesignBasics #TShirtPrintingTips #DesignAccuracy #PrintTemplates #EdgeToEdgePrint #SublimationPrinting #DesignForPrint #CustomApparelDesign #GraphicDesignTips #PrintingProcess #ProfessionalPrinting #ClothingDesign #PrintSetup #DTGPrinting #GarmentPrinting #CreativeDesign #MockupDesign #PrintQuality #TShirtDesign #DesignMargins #ProductionReadyDesign #PrintLikeAPro #TextileDesign