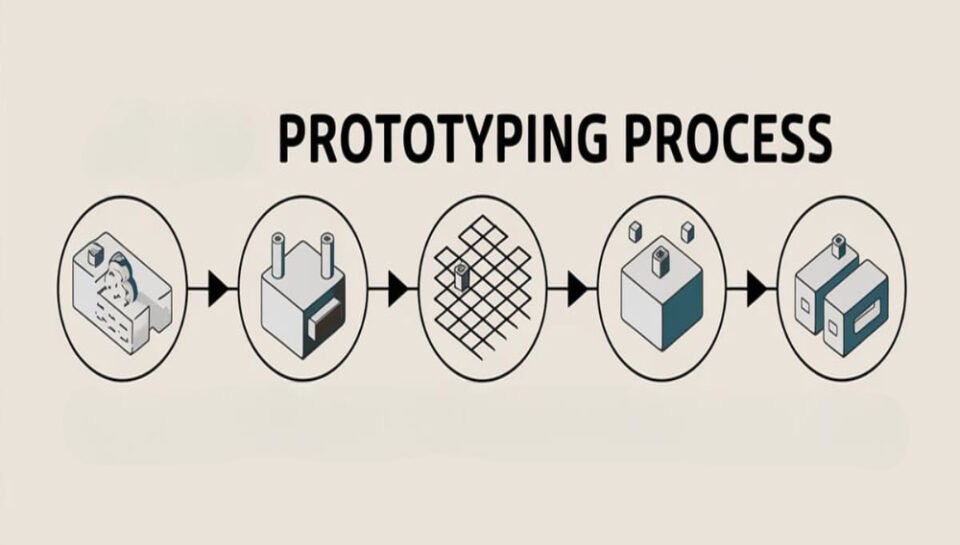

Detail the process of prototyping in package design.

INTRODUCTION

Prototyping is a critical step in the package design process that bridges the gap between concept and production. It involves creating a tangible or visual model of the packaging to evaluate its aesthetics, functionality, structure, and user interaction before mass manufacturing. This stage allows designers, clients, and stakeholders to test, refine, and validate the design to ensure it meets all practical, brand, and consumer expectations. Below is a detailed breakdown of the prototyping process in package design.

1. DESIGN FINALIZATION AND SPECIFICATION REVIEW

Before prototyping begins, the structural and graphic design concepts must be finalized. This includes dielines, dimensions, material specifications, color codes, print finishes (like embossing, foil, matte/gloss), and placement of visual elements. Ensuring accurate and production-ready artwork is essential for a realistic prototype.

2. SELECTION OF MATERIALS

The prototyping team selects materials that closely match the final packaging material—such as cardboard, plastic, glass, or sustainable alternatives. While some prototypes use cheaper or simulated materials for early-stage review, high-fidelity prototypes use exact materials to test durability and finish quality.

3. CREATION OF STRUCTURAL MOCKUPS

Physical structural prototypes are produced, often by hand or using equipment like die cutters, 3D printers, or laser cutters. These mockups help assess shape, foldability, size accuracy, stackability, and ergonomics. For complex packaging, engineering models may also simulate assembly, sealing, and opening mechanisms.

4. APPLICATION OF GRAPHIC DESIGN ELEMENTS

Once the structure is approved, the visual design is applied to the prototype. This may involve printing on label stock, directly on the package, or wrapping digital prints onto mockups. Designers ensure that typography, imagery, brand colors, and logos appear correctly when applied to the 3D surface.

5. FUNCTIONALITY TESTING

The prototype undergoes real-world testing to check usability and practicality. This includes opening and closing mechanisms, tamper evidence, ease of handling, shelf placement, and how well the packaging protects the product. If it’s a resealable package or has an ergonomic design, its effectiveness is assessed here.

6. AESTHETIC EVALUATION

Stakeholders evaluate how the package looks and feels. Factors like color fidelity, print quality, finish texture, and visual appeal are reviewed. Any inconsistencies in design execution can be identified and corrected before final production.

7. USER FEEDBACK AND MARKET TESTING

In some cases, prototypes are shared with test groups or internal teams to gather user feedback. Observing how consumers interact with the packaging can uncover unexpected issues or opportunities for improvement. This feedback informs revisions in structure, messaging, or visuals.

8. COST AND MANUFACTURABILITY ASSESSMENT

Prototypes help evaluate cost-efficiency and production feasibility. Manufacturers assess whether the design is easy to mass-produce, what modifications might reduce costs, and how it fits into existing manufacturing systems. Prototyping allows adjustments to avoid expensive errors during large-scale production.

9. FINAL REVISIONS AND APPROVAL

Based on internal reviews, user feedback, and manufacturing input, the prototype is refined and finalized. This may involve minor changes in dielines, text placement, or material choice. Once all stakeholders approve the prototype, it moves into the prepress and production stages.

10. DOCUMENTATION AND PRODUCTION TRANSFER

Detailed specifications, including dieline files, color standards, material types, and finishing details, are documented and sent to production teams. The prototype serves as a reference sample during manufacturing to ensure consistent quality and adherence to the approved design.

HASHTAGS

#PackagingPrototype #DesignToProduction #PrototypingProcess #PackageDesign #ProductDevelopment #StructuralDesign #PrintMockup #PackagingWorkflow #DesignValidation #CreativePackaging #PackagingTesting #UserTesting #MaterialSelection #PackagingFunctionality #RetailPackaging #3DMockup #PackagingVisualization #BrandPackaging #PackagingEngineering #DesignRefinement #ManufacturingReady #PackagingSamples #PackagingFeedback #PrototypeEvaluation #PackagingInnovation