Detail the steps involved in the package design process.

INTRODUCTION

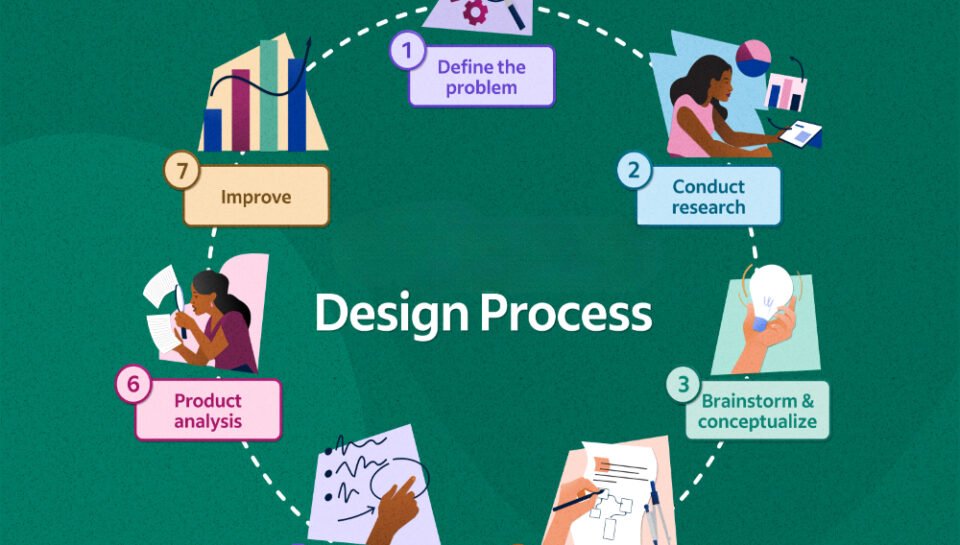

The package design process is a structured blend of strategic planning, creative thinking, and technical execution. It transforms a product’s brand identity into a tangible, user-focused, and shelf-ready form. Whether launching a new product or rebranding an existing one, an effective packaging design process ensures that the final output is both visually compelling and functionally practical. This article outlines the essential steps involved in creating impactful and market-ready package design.

1. RESEARCH AND DISCOVERY

The first step in the package design process involves comprehensive research. Designers and marketers gather information about the product, brand history, competitor packaging, consumer behavior, and industry trends. Understanding market expectations, regulatory requirements, and environmental concerns provides a solid foundation for informed design decisions.

2. DEFINING OBJECTIVES AND STRATEGY

Clear objectives must be established based on insights from research. These include identifying the target audience, defining the product’s unique selling proposition (USP), setting the tone of the design (luxury, fun, organic, tech-savvy, etc.), and determining functional goals such as durability or sustainability. This step sets the direction for the design and ensures alignment with broader marketing strategies.

3. CONCEPT DEVELOPMENT

Once the strategy is defined, designers brainstorm and sketch multiple concepts. This is the creative phase where different structural and visual styles are explored. Mood boards, rough sketches, and digital mockups are created to visualize ideas. These concepts reflect how the packaging will look, feel, and function.

4. STRUCTURAL DESIGN AND MATERIAL SELECTION

This step involves engineering the physical form of the package. Decisions are made regarding dimensions, shapes, openings, closures, and material types (e.g., cardboard, plastic, glass, or eco-friendly alternatives). Functional requirements such as product protection, ease of storage, and shipping considerations are key.

5. GRAPHIC DESIGN AND BRAND INTEGRATION

With the structure in place, graphic designers begin incorporating visual elements—logos, typography, brand colors, imagery, and regulatory information. This step ensures the design communicates the brand effectively while adhering to visual hierarchy and aesthetic balance. The layout must also comply with printing specifications.

6. PROTOTYPING AND MOCKUPS

Designs are brought to life through physical or digital prototypes. These mockups help evaluate the appearance, usability, and fit of the packaging. Clients, designers, and stakeholders can assess the overall feel, spot design flaws, and suggest improvements before moving into production.

7. FEEDBACK AND REFINEMENT

Based on feedback from internal teams, test audiences, or client reviews, adjustments are made to the design. This iterative process ensures the packaging meets all functional and emotional criteria. Revisions may involve structural tweaks, content edits, or visual enhancements.

8. TESTING AND VALIDATION

Before full-scale production, the packaging undergoes testing to assess durability, shelf life, print quality, and consumer interaction. Drop tests, moisture resistance, temperature tolerance, and usability evaluations ensure the packaging performs in real-world conditions.

9. FINALIZATION AND PREPRESS PREPARATION

Once the design is approved, final files are prepared for printing. This involves ensuring color accuracy (CMYK), setting up dielines, adding bleeds, confirming resolution, and providing print-ready PDFs. All technical specifications are double-checked to avoid production issues.

10. PRODUCTION AND QUALITY CONTROL

The package design is sent to print or manufacturing partners for production. During this stage, print proofs and sample runs may be reviewed to ensure quality consistency. Any discrepancies are addressed before the full order is produced and distributed.

11. LAUNCH AND PERFORMANCE MONITORING

Once the packaging is on shelves or in e-commerce, its performance is monitored through sales data, customer feedback, and market response. This post-launch analysis helps evaluate the success of the design and informs future improvements or redesigns.

HASHTAGS

#PackageDesignProcess #PackagingWorkflow #CreativeDesignProcess #BrandPackaging #PackagingStrategy #DesignDevelopment #ProductPackaging #PackagingResearch #StructuralDesign #GraphicDesign #PackagingPrototype #FeedbackLoop #PackagingProduction #PrepressDesign #MaterialSelection #PackagingTrends #DesignTesting #QualityControl #FunctionalPackaging #UserExperienceDesign #VisualBranding #PackagingLaunch #EcoPackaging #PackagingDesignSteps #CreativePackaging